5 Key Tips to Choose the Best Manufacturers for Your Global Sourcing Needs

In today’s rapidly evolving global economy, selecting the right manufacturers for your sourcing needs has never been more critical. According to a report by Smithers Pira, the global manufacturing sector is projected to reach over $40 trillion by 2025, underscoring the immense scale and significance of manufacturing in international trade. As businesses increasingly look to optimize costs and enhance operational efficiency, navigating the complexities of manufacturers' certifications and compliance has become paramount. The Intermodal Association estimates that over 75% of trade globally is conducted through imports and exports, highlighting the importance of identifying reliable manufacturers who meet stringent import and export certifications. By understanding these dynamics, companies can better position themselves in the competitive landscape, ensuring they select manufacturers that align with their specific sourcing strategies and quality standards.

Identifying Your Specific Sourcing Requirements for Success

Identifying your specific sourcing requirements is crucial for successful global sourcing. A thorough understanding of your needs can dramatically influence your procurement strategy and supplier selection process. Data and analytics technologies are increasingly becoming a top priority for investment in strategic sourcing, with a focus on tailoring sourcing approaches based on detailed market insights. According to recent studies, organizations leveraging advanced data analytics in their procurement strategies report a 20% improvement in cost savings and supplier performance. This demonstrates the need to clearly define business objectives and sourcing criteria before engaging with potential manufacturers.

Moreover, with the rise of artificial intelligence, companies are now prioritizing technology to enhance their procurement processes. Research indicates that 96% of companies recognize AI as critical for long-term business success. Embracing generative AI can streamline supplier identification and negotiation efforts, enabling procurement teams to make data-driven decisions that align closely with identified sourcing requirements. By employing such technologies, businesses can enhance their competitive edge, ensuring that they choose manufacturers that not only fit their logistical needs but also align with their strategic goals.

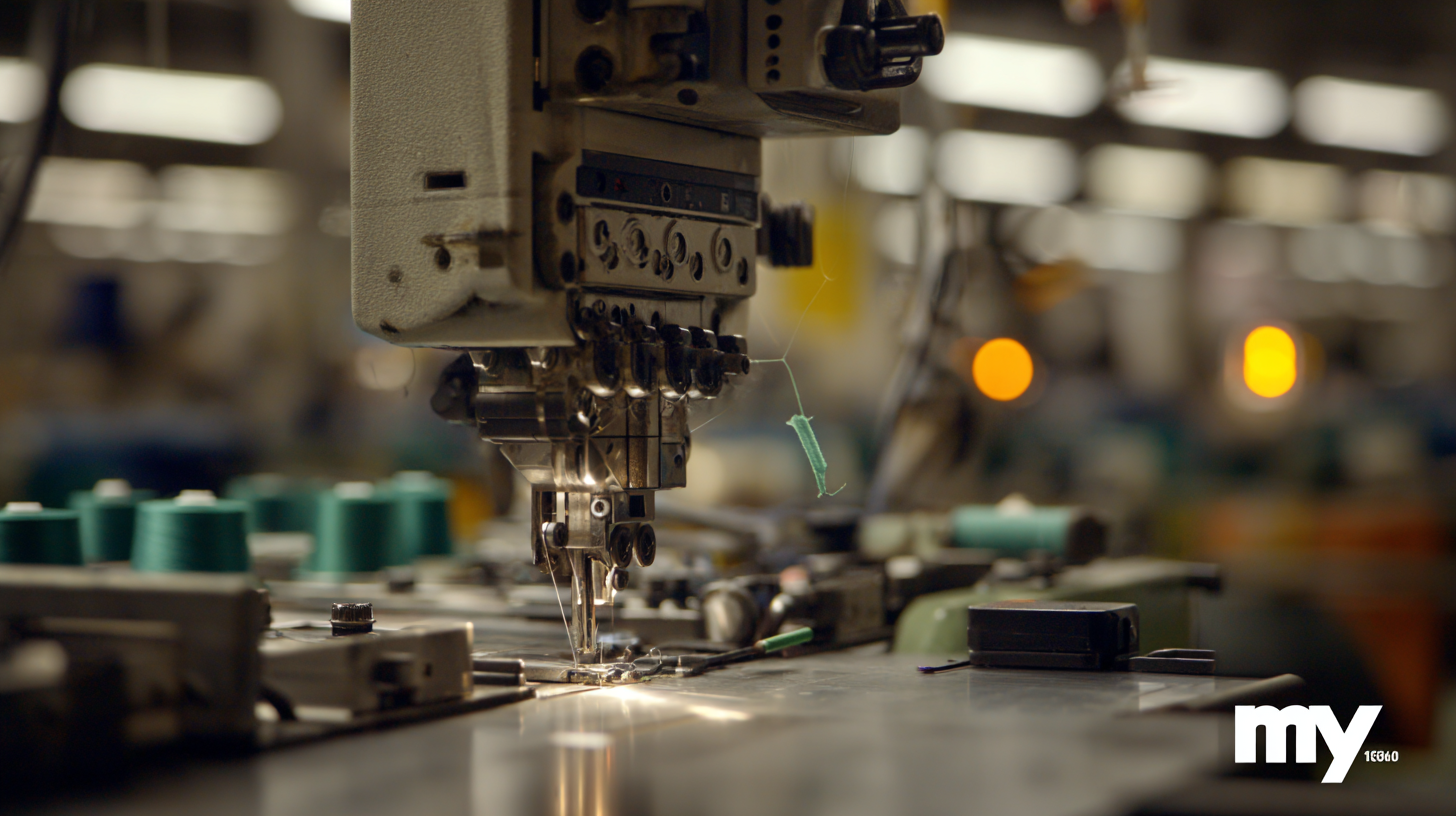

Evaluating Manufacturer Credentials and Industry Experience

When it comes to global sourcing, evaluating a manufacturer's credentials and industry experience is crucial. Start by reviewing their certifications, such as ISO standards or industry-specific regulations that reflect their commitment to quality and safety. These credentials provide insight into a manufacturer's operational processes and adherence to best practices. A well-certified manufacturer not only assures quality products but also minimizes risks associated with sourcing.

Additionally, industry experience plays a significant role in a manufacturer's ability to meet your specific needs. Look for manufacturers who have a proven track record in your desired sector. Their experience often translates into a deeper understanding of market trends, potential challenges, and customer preferences. Consider conducting interviews or visiting their facilities to assess their expertise firsthand. A manufacturer with extensive industry knowledge will be better equipped to offer innovative solutions and maintain flexibility in adapting to changing requirements, ensuring a successful partnership in your sourcing strategy.

Assessing Quality Control Standards and Compliance Measures

Assessing quality control standards and compliance measures is critical in global sourcing, as it directly impacts the trust clients place in manufacturers. Mastering quality control compliance has become a focal point for businesses seeking reliable outsourcing partners. According to a recent industry report, 70% of companies that prioritize quality compliance see a marked increase in customer satisfaction and retention. This underscores the necessity of adopting stringent quality control measures.

To ensure effective quality control, companies should implement regular audits and monitor compliance with established standards. One key tip is to develop a comprehensive checklist that outlines necessary quality metrics applicable to your manufacturing partners. This includes adherence to international standards such as ISO 9001, which emphasizes continuous improvement and customer satisfaction. Another essential practice is fostering open communication with suppliers about quality expectations and compliance requirements. By establishing a robust framework for accountability, organizations can significantly mitigate risks while enhancing product quality.

Moreover, it's vital to stay updated on evolving compliance regulations, as non-compliance can lead to significant financial repercussions. A recent study revealed that businesses that actively engage in compliance training for their employees experience a 40% reduction in compliance-related incidents. By investing in quality control knowledge and procedures, companies not only protect their brand reputation but also build long-lasting relationships with their clients.

Exploring Communication and Support Throughout the Sourcing Process

Effective communication is crucial when selecting the right manufacturers for your global sourcing needs. When exploring potential partners, assess how responsive and transparent they are in their communications. A manufacturer that prioritizes open dialogue can help mitigate misunderstandings and ensure that both parties are aligned on project goals and expectations. Look for companies that provide multiple communication channels—be it email, phone, or instant messaging—to facilitate quick and efficient exchanges, particularly across different time zones.

Support throughout the sourcing process also plays a vital role in choosing the right manufacturer. Assess the level of post-production support offered, including quality control, shipping, and after-sales service. A manufacturer with strong support systems can troubleshoot issues more effectively, enhancing your operational efficiency. Additionally, inquire about their experience with international shipping regulations and customs, as having a knowledgeable partner can significantly reduce potential delays and costs. By focusing on these communication and support aspects, you can establish a strong foundation for a successful long-term partnership.

Understanding Cost Structures and Payment Terms for Sustainable Partnerships

When choosing manufacturers for your global sourcing needs, understanding cost structures and payment terms is crucial for establishing sustainable partnerships. A recent report by McKinsey indicates that organizations that actively manage their supply chain relationships can reduce costs by up to 15% and improve overall operational efficiency. This is particularly important in an increasingly competitive landscape, where every percentage point saved can significantly impact the bottom line.

One essential aspect to consider is the pricing model adopted by potential manufacturers. Whether they utilize cost-plus pricing, market-based pricing, or value-based pricing can influence not only the price but also the quality and service you receive. According to a survey by Deloitte, nearly 80% of companies identify payment terms as a major factor in evaluating potential partnerships, which emphasizes the need for clarity and mutual understanding in these agreements. By ensuring that both parties agree on payment schedules and methods, companies can foster transparency and build trust, which are foundational elements of successful long-term partnerships.

5 Key Tips to Choose the Best Manufacturers for Your Global Sourcing Needs

| Manufacturer Type | Location | Cost Structure | Payment Terms | Lead Time |

|---|---|---|---|---|

| Electronics | China | Material Costs + Labor | 30% Upfront, 70% on Delivery | 6-8 Weeks |

| Textiles | India | Cost per Unit + Shipping | 50% Upfront, 50% on Shipment | 4-6 Weeks |

| Furniture | Vietnam | Fixed Pricing + Material Costs | 40% Upfront, 60% Before Shipping | 8-10 Weeks |

| Automotive Parts | Germany | Cost per Component | 30% at Order, 70% Net 30 | 6 Weeks |

| Consumer Goods | Mexico | Variable Costs | Full Payment Before Production | 5-7 Weeks |